K&E Co., Ltd. pioneers a market for global expansion.

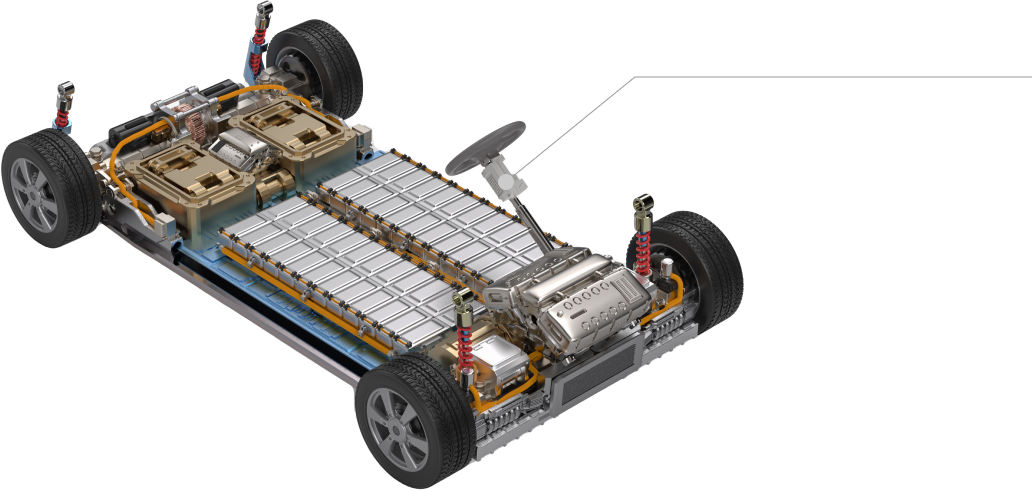

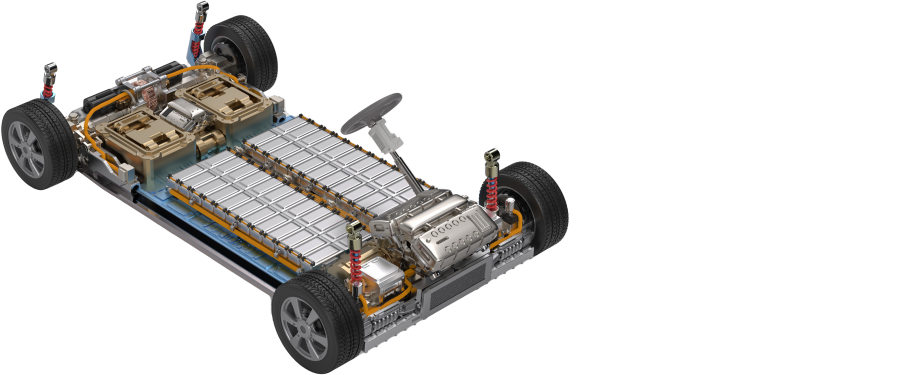

Our Torque Sensor parts, essential for Electric Power Steering (Driving Power Steering), are made of a nickel (MDPS-Motor Nickel) alloy, maximizing permeability through precision stamping and high-temperature hydrogen heat treatment processes.

Venturing into the automotive

sensor parts business

Total Part Model Quantity

1 R&D Center / 3 Factories in Korea

/ 1 Corporation in Vietnam

As the demand for eco-friendly hybrid automobiles (e.g. electric and hydrogen vehicles), the press component for magnetic torque sensors, the core component of the MDPS system, has been developed through the precise drawing method, which are being mass-produced under stable quality management.

We are manufacturing core parts of the magnetic torque sensor applied to the MDPS system, a type of an automobile steering mechanism, in the precise drawing method and hot hydrogen heat treatment method. Through this, we are performing an important role in satisfying high performance and eco-friendliness.

FeNi-Alloy (special alloy) material is used for precision stamping

Maximizing characteristics through high-temperature hydrogen heat treatment

Quality stability is ensured by analyzing changes due to high-temperature hydrogen heat treatment

Manufacture as a jointless integral product without using the drawing method

Torque Sensor

TOP

TOP